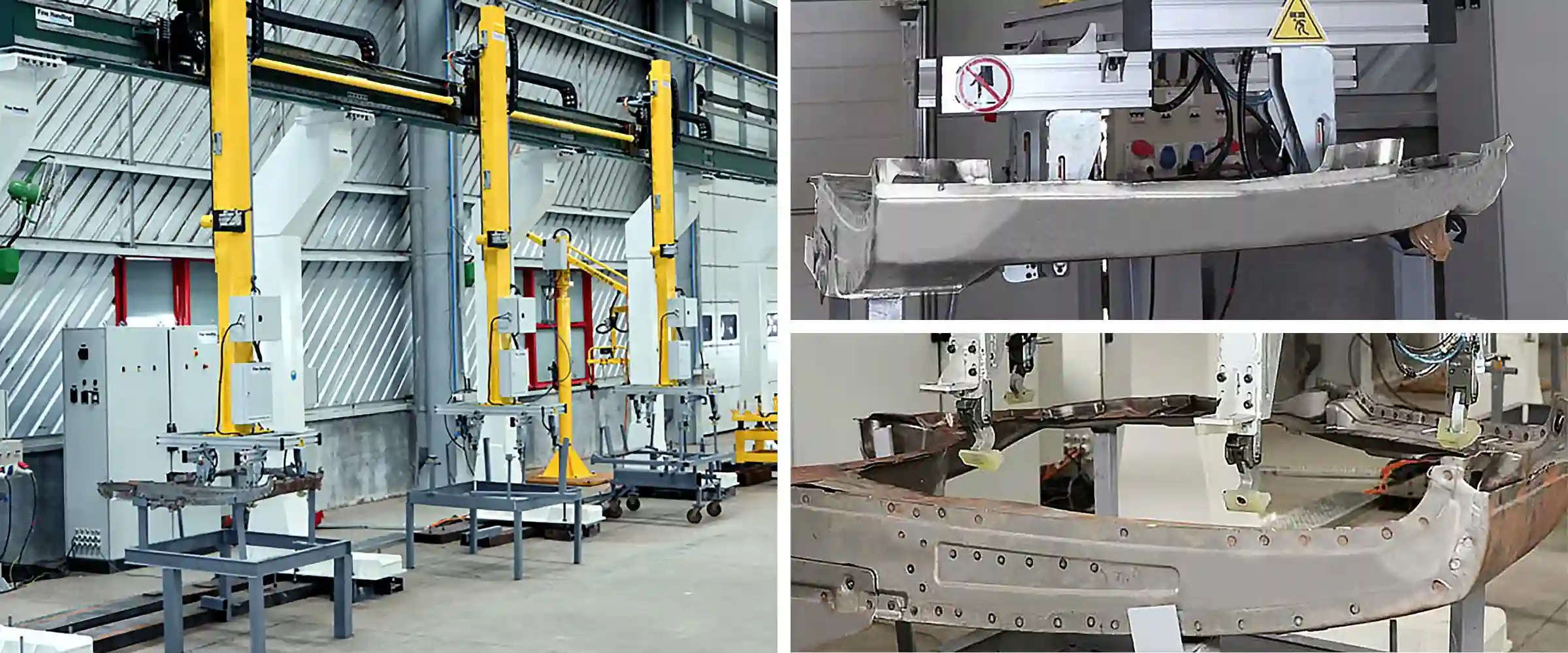

Tractor Hood and Bonnet Handling

Industrial manipulators and custom grippers play a crucial role in the efficient and safe handling of hoods in various industrial applications. Bonnet/Hood handling poses unique challenges, and these solutions address them effectively while improving ergonomics, safety, and cycle times.

Improve ergonomics when lifting, carrying or manipulating Tractor Hood and Bonnet

Manipulators guarantee precise hood placement, minimizing misalignment risks. These solutions lessen worker strain by automating lifting and positioning tasks. Grippers, with sensors, boost safety by detecting obstacles and adjusting their grip accordingly.

- Hoods can be heavy and cumbersome, making manual handling risky and inefficient.

- Mishandling hoods can result in injuries and damage to the product.

- Repetitive manual lifting can lead to worker fatigue and musculoskeletal issues.

- Manual handling often slows down production processes.

Automation cuts cycle times, boosting productivity overall. Grippers are customized to handle bonnet/hoods of different sizes, shapes, and materials. Automated processes ensure consistency in hood handling, enhancing product quality. Less manual work and fewer mistakes save costs.

In summary, industrial manipulators and customized grippers streamline bonnet/hood handling processes, enhancing worker safety, ergonomics, and efficiency, while offering flexibility for diverse applications.