Handling Clutch Housing

Clutch Housing is a part of the engine/power train line that is typically presented horizontally and placed vertically onto the machine.

Improve ergonomics when lifting, carrying or manipulating Clutch Housing

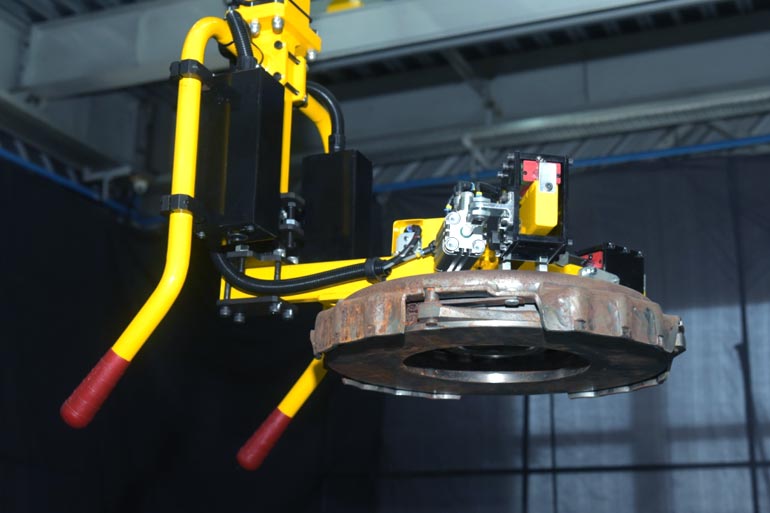

Fine Handling has developed an innovative gripper equipped with an orientation change mechanism specifically designed for handling clutch housings.The orientation change mechanism enables the gripper to provide rotation functionality, allowing clutch housings to be easily repositioned as needed during the handling process.

- Automotive clutch housings can be heavy, requiring appropriate lifting equipment and techniques to prevent strain or injuries to operators.

- The complex and often irregular shapes of clutch housings can make them challenging to grip and maneuver, especially in confined spaces.

- Some clutch housing assemblies may include fragile components, such as sensors or connectors, which require careful handling to prevent breakage or malfunction.

Customized grippers provide a secure grip on clutch components, minimizing the risk of accidental drops or mishandling. Industrial manipulators are equipped with collision detection systems to prevent accidents and protect both workers and equipment.

Clutch housings, integral components of engine/powertrain assembly lines, are conventionally presented horizontally and then vertically placed onto machines. Fine Handling introduces an adaptable gripper with an orientation change mechanism tailored for clutch housings. This mechanism allows rotational movement, accommodating various sizes and shapes of components. Moreover, the gripper possesses orientation capacity to tilt the component, ensuring precise positioning during handling. Additionally, Fine Handling has effectively implemented a distinctive interchangeable gripping system specifically designed for clutch housings, enhancing flexibility and efficiency in assembly operations.