Gantry Systems for transfer of Automotive Doors

Gantry Systems for transfer of Automotive Doors

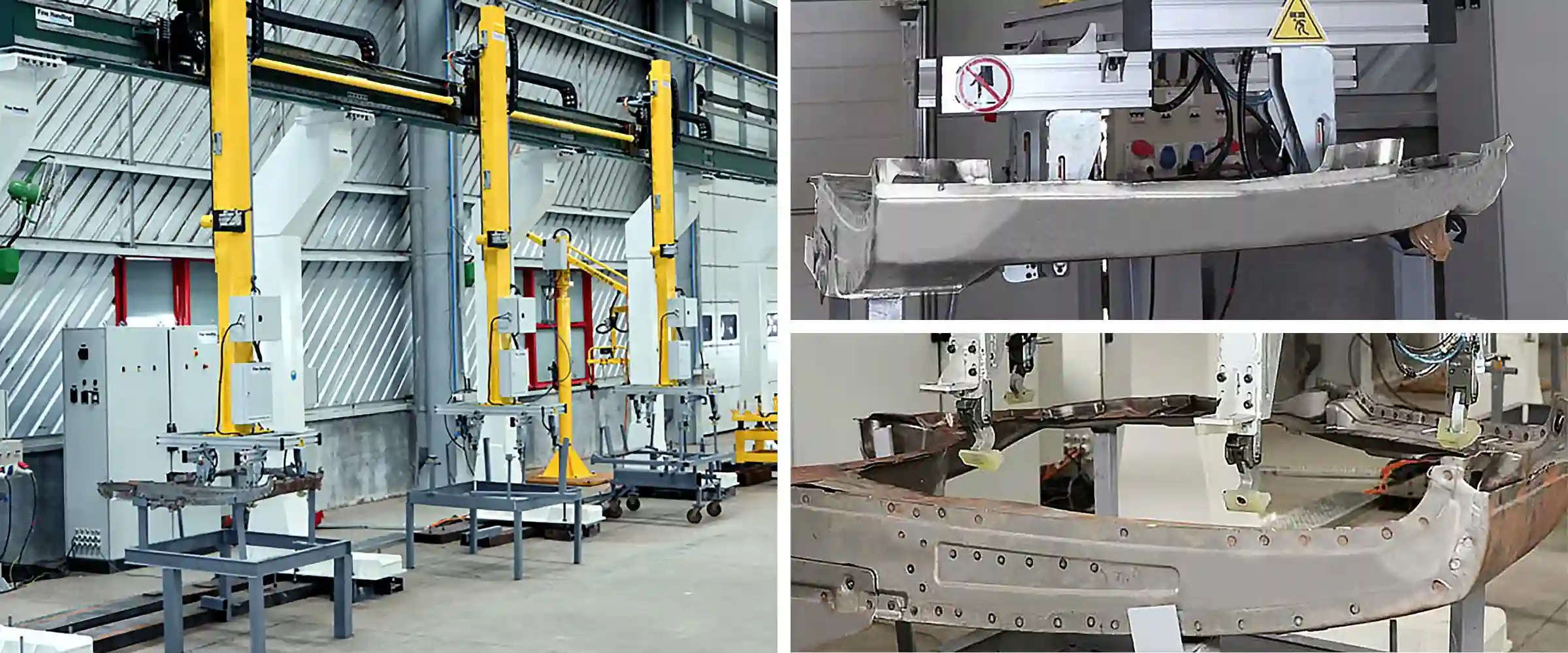

Gantry systems for loading and stacking present a versatile and uncomplicated solution for automating various production lines and processes. Each system is tailor-made to meet specific customer needs, finding applications in general handling technology, flexible production setups, and tasks like automatic press loading and unloading, showcasing their wide-ranging utility.

Challenges

- Safe gripping for sheet metal components prone to bending or being flexible while handling

- Transfer from one station to another on the weld shop

- Position sensing in case failure or breakdown

- Precise placement on the fixture

Solution and Benefits

- Lift Innovative gripper was developed with two PU Jaws which clamp the component and also factor in bow shape formed during lifting.

- Transfer Specialised induction motor based gantry was developed for smooth transfer from one station to another.

- Position sensor were already provided however in case of failure/breakdown system was not able determine its position/home position, Advanced encoder was installed with enabled gantry system to automatically determine its position and continue with the process.

- Encoder not only solved the home position problem but it also helps to achieve precise placement.

- Gantry door was required to be made vertical from its horizontal position, Innovative Turn table was developed to change the orientation and column mounted manipulator was provided to quickly pick the component and transfer to next process.