Solar Panel

Solar panels are fragile and can easily crack or break if mishandled, leading to costly damage and reduced efficiency. Handling solar panels presents several challenges due to their size, fragility, and weight.

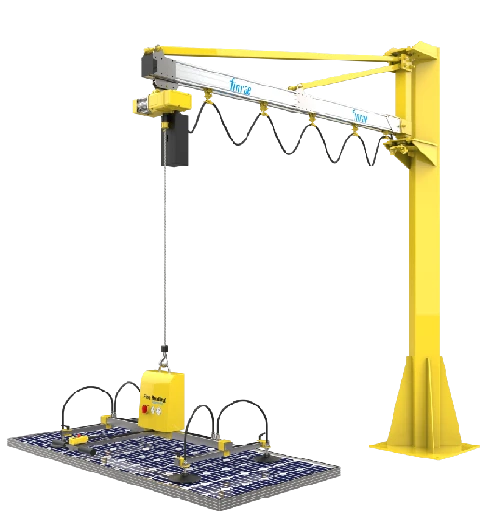

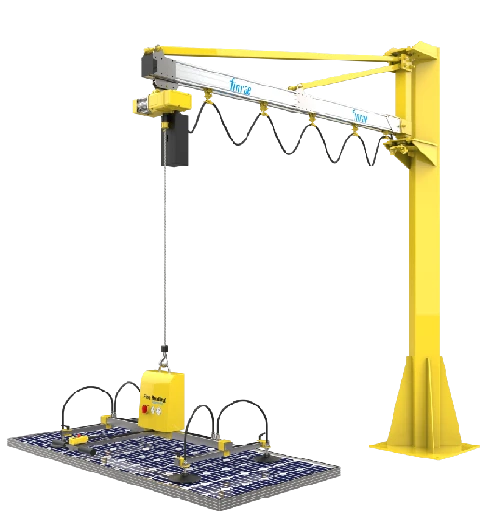

Improve ergonomics when lifting, carrying or manipulating Solar Panel

Industrial Manipulators Automation speeds up production by cutting cycle times and getting rid of delays from manual handling. Automated systems carefully position and align the frame, making sure parts fit perfectly. This means every 3-wheeler frame is handled and assembled the same way every time, removing differences from human error.

- Solar panels can be large and heavy, especially for commercial installations, making them difficult to lift, transport, and position safely.

- Mishandling of solar panels can pose safety risks to workers, such as accidents, injuries, or falls, particularly when working at heights during installation.

- Proper alignment and positioning of solar panels are crucial for optimal performance and efficiency of the solar array.

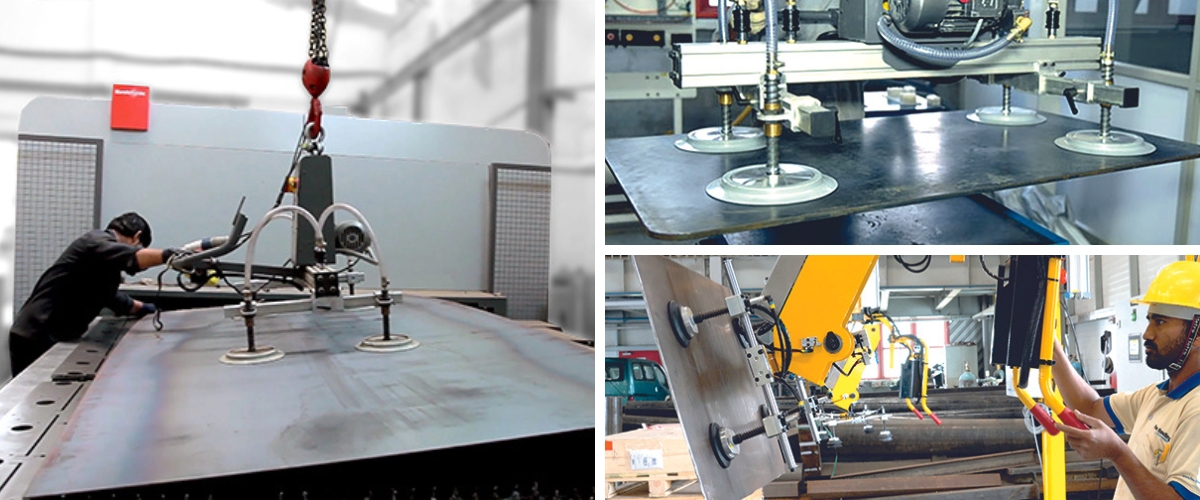

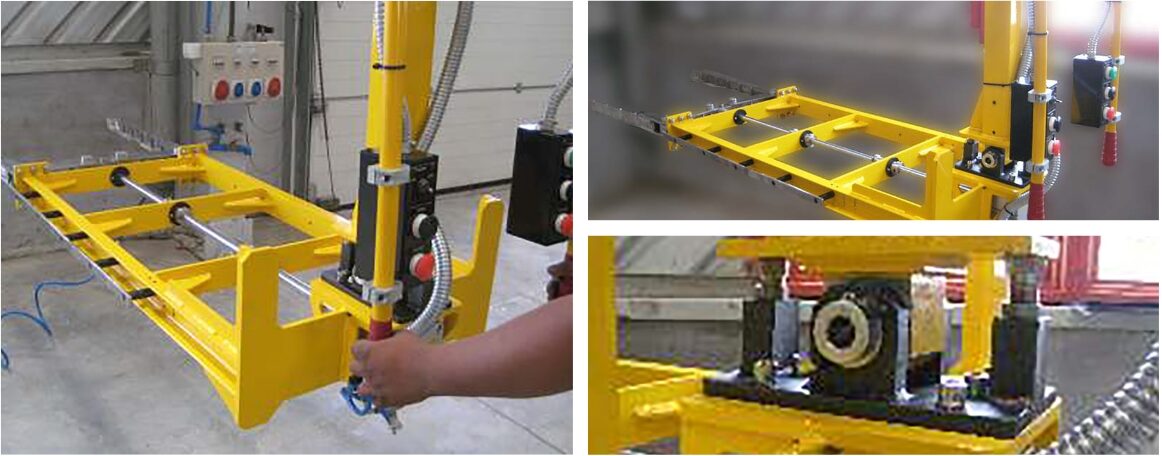

Fine's Industrial manipulators equipped with soft-touch grippers or suction cups provide gentle handling of solar panels, minimizing the risk of damage or breakage during lifting and positioning. Grippers specifically designed for solar panels ensure a secure and precise grip, even on fragile or irregularly shaped panels. These grippers can accommodate different panel sizes and types, providing versatility and flexibility in handling tasks.

Our industrial manipulators and customized grippers come with built-in safety features such as overload protection, emergency stop buttons or automatic release mechanisms, ensuring a safe working environment. Overall, industrial manipulators and customized grippers streamline solar panel handling processes, improving efficiency, safety and productivity in solar panel manufacturing, installation and maintenance.