Furniture Components and Products Handling

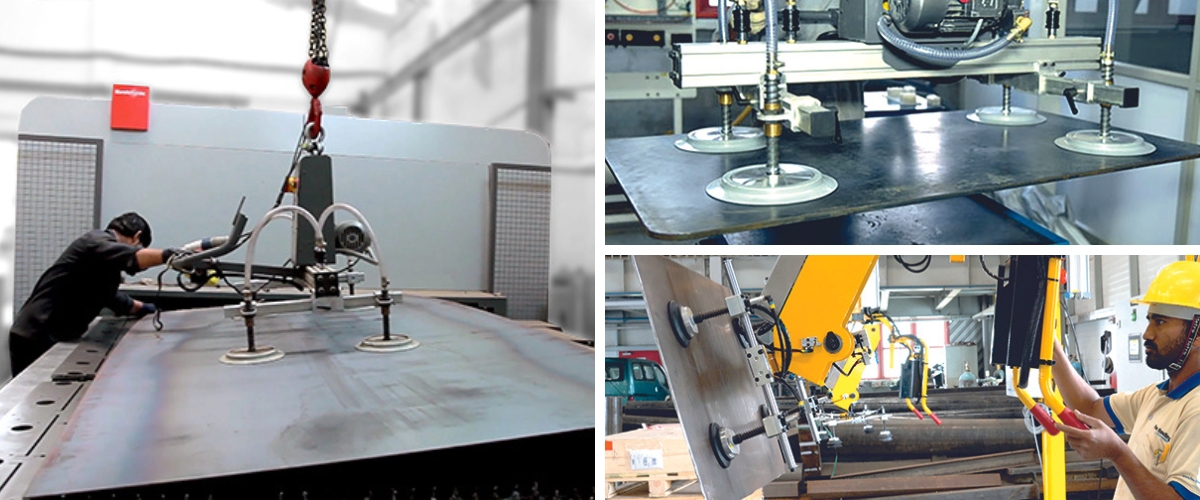

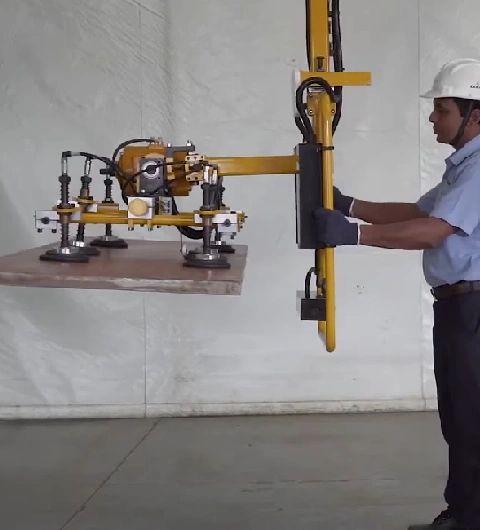

Manipulators are a must for a modern furniture workshop aiming for fast paced and high quality production. Equipped with lifting capabilities, Manipulators can assist in lifting and maneuvering heavy wooden planks, reducing the physical strain on workers.

Improve ergonomics when lifting, carrying or manipulating Furniture Components and Products

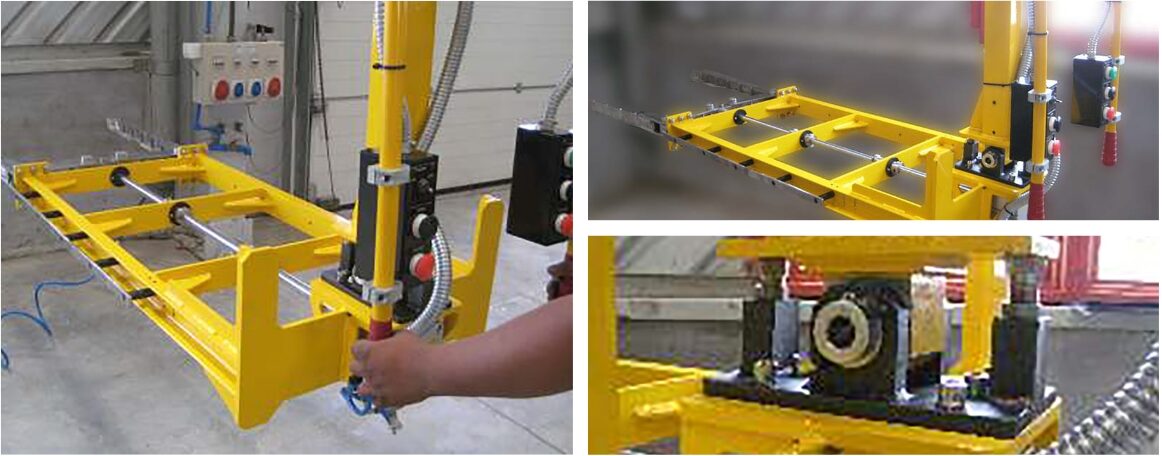

Handling with manipulators reduces complexity, can save space and prevent the risks of accidents and product damage in the production process. Manipulators can be customized with specialized gripping tools to handle awkward shapes and sizes of wooden planks efficiently and securely.

- Wooden planks used in furniture manufacturing can be extremely heavy, making manual handling difficult and posing risks of strain or injury to workers.

- Awkward Shapes and Sizes of Wooden planks can be cumbersome to handle, especially during cutting, binding and joining processes on machines.

- Heavy wooden planks can pose safety hazards if not handled properly, including the risk of falling, crushing, or causing accidents in the workplace.

- Manual handling of heavy wooden planks can slow down production processes, affecting overall efficiency and productivity.

Manipulators offer precise control over movements, enabling accurate positioning of wooden planks during cutting, polishing, and joining processes, leading to assured product quality.

Manipulators are equipped with safety features such as sensors and emergency stop buttons, reducing the risk of accidents associated with manual handling of heavy materials. By automating material handling tasks, manipulators can significantly improve efficiency and productivity in furniture manufacturing, allowing workers to focus on more skilled tasks.