Handling solutions for heavy paper and plastic rolls

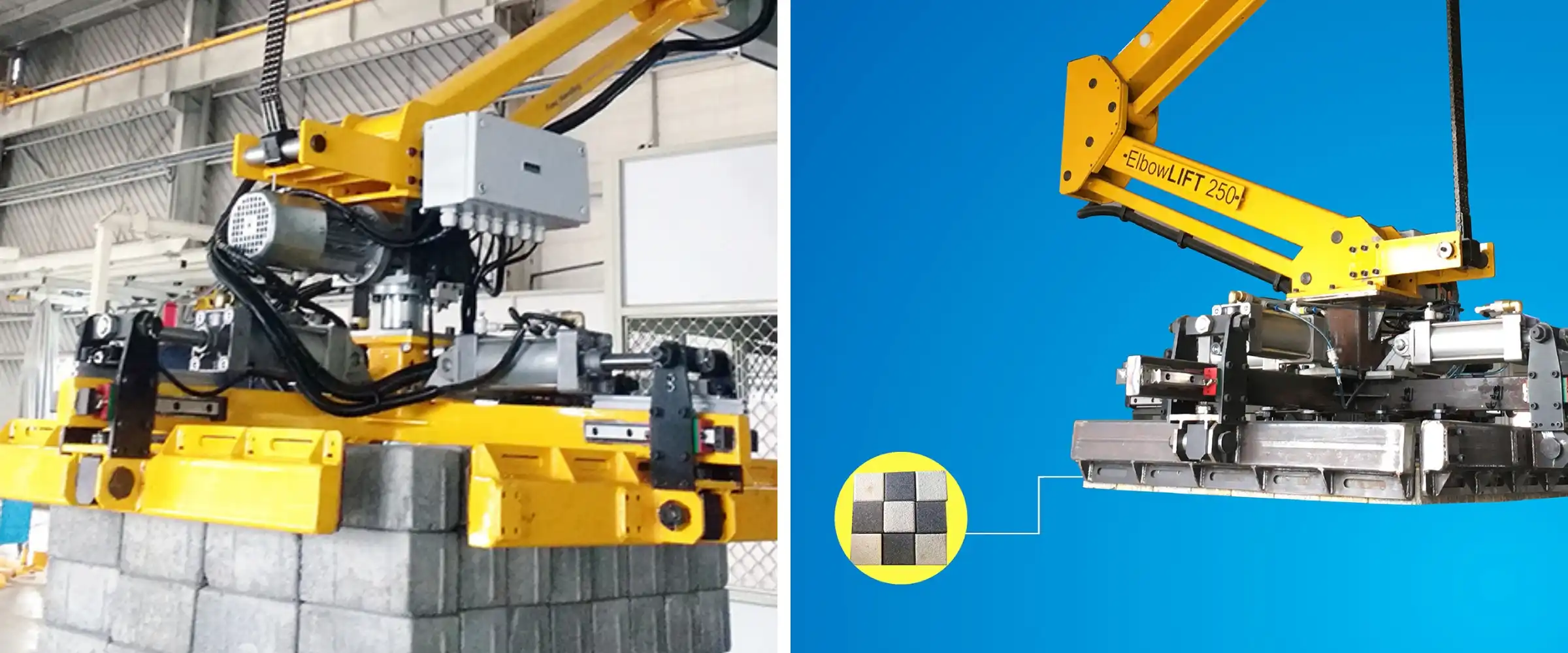

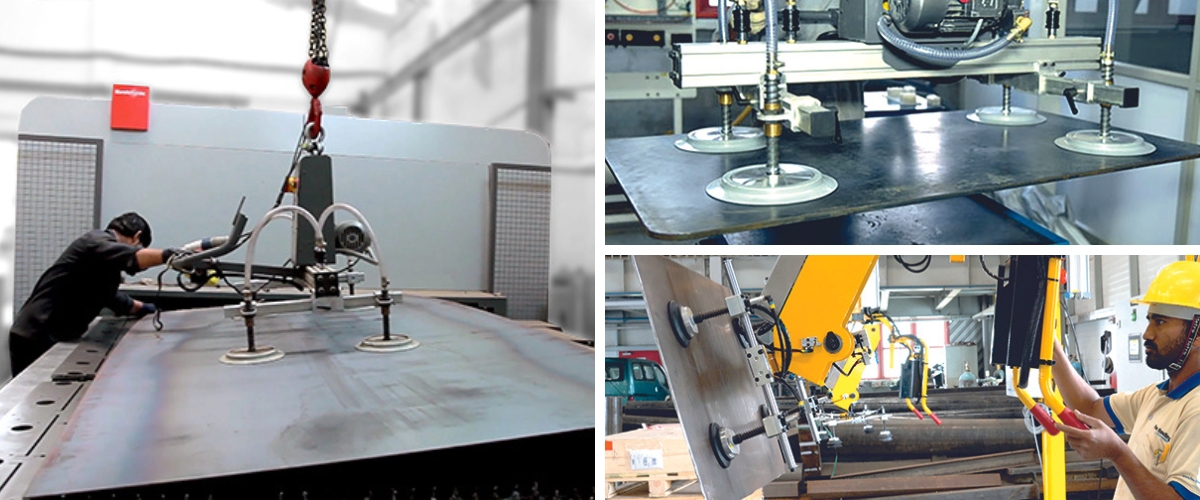

The use of Manipulators offers precise control over the movement and placement of packaging rolls, ensuring accurate positioning on the machines. Tailored grippers can be designed to securely handle different packaging rolls, accommodating variations in size, shape and material.

Improve ergonomics when lifting, carrying or manipulating Packaging Paper and Rolls

- Manual handling of heavy packaging rolls can pose significant safety risks, including musculoskeletal injuries such as strains, sprains, and back injuries to workers.

- Without proper lifting equipment, there's a higher likelihood of accidents and mishaps occurring during the loading process, leading to potential injuries or damage to equipment and products.

- Manual loading can be time-consuming and inefficient, leading to production bottlenecks and decreased overall productivity.

- Inconsistent placement of packaging rolls on machines, potentially leading to operational issues, product defects, or downtime for adjustments.

- Unsafe or inefficient working conditions can negatively impact employee morale and job satisfaction.

By automating loading tasks, industrial manipulators and custom grippers can package handling significantly improve workflow efficiency and overall productivity.

Minimizing manual handling reduces the risk of workplace injuries, creating a safer working environment for employees. Automated handling ensures consistent placement of packaging rolls, leading to improved product quality and reduced waste.