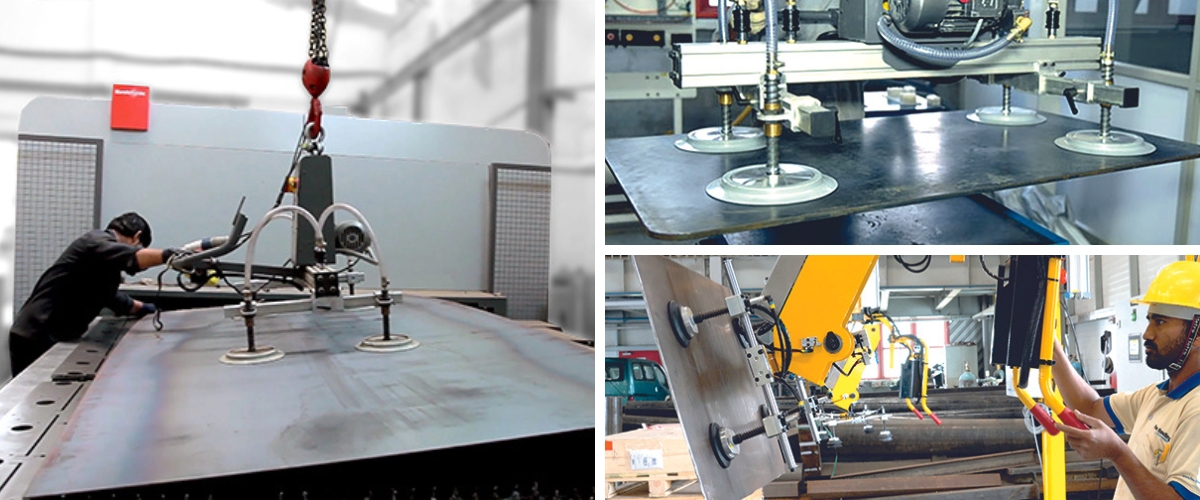

Metal Sheet Handling

Handling metal sheets can pose various risks to individuals, depending on the type of metal, its size, shape, and the equipment used. Solutions from Fine Handling helps to address critical and common risks associated with handling metal sheets.

Improve ergonomics when lifting, carrying or manipulating Metal Sheet

Manipulators with vacuum grippers assist workers in lifting and positioning heavy metal sheets, reducing the risk of musculoskeletal injuries. Customized grippers offer precise handling, minimizing the need for manual adjustments and reducing operator fatigue. Customized grippers ensure uniform grip and release, preventing damage to delicate metal sheets.

- Metal sheets often have sharp edges, burrs, or jagged surfaces that pose risks if not handled carefully.

- Metal sheets can be quite heavy, and large. Improper lifting techniques can lead to back, neck, or muscle injuries.

- When handling metal sheets with equipment like cranes, forklifts, or clamps, there is a risk of safety

- Metal sheets can become extremely hot when subjected to welding, cutting, or other fabrication processes, posing a risk of burns to those handling them

Manipulators enable quicker handling of sheets, reducing production downtime of costly machines such as bending, cutting etc. Customized grippers allow for seamless integration into automated workflows, optimizing overall cycle times.