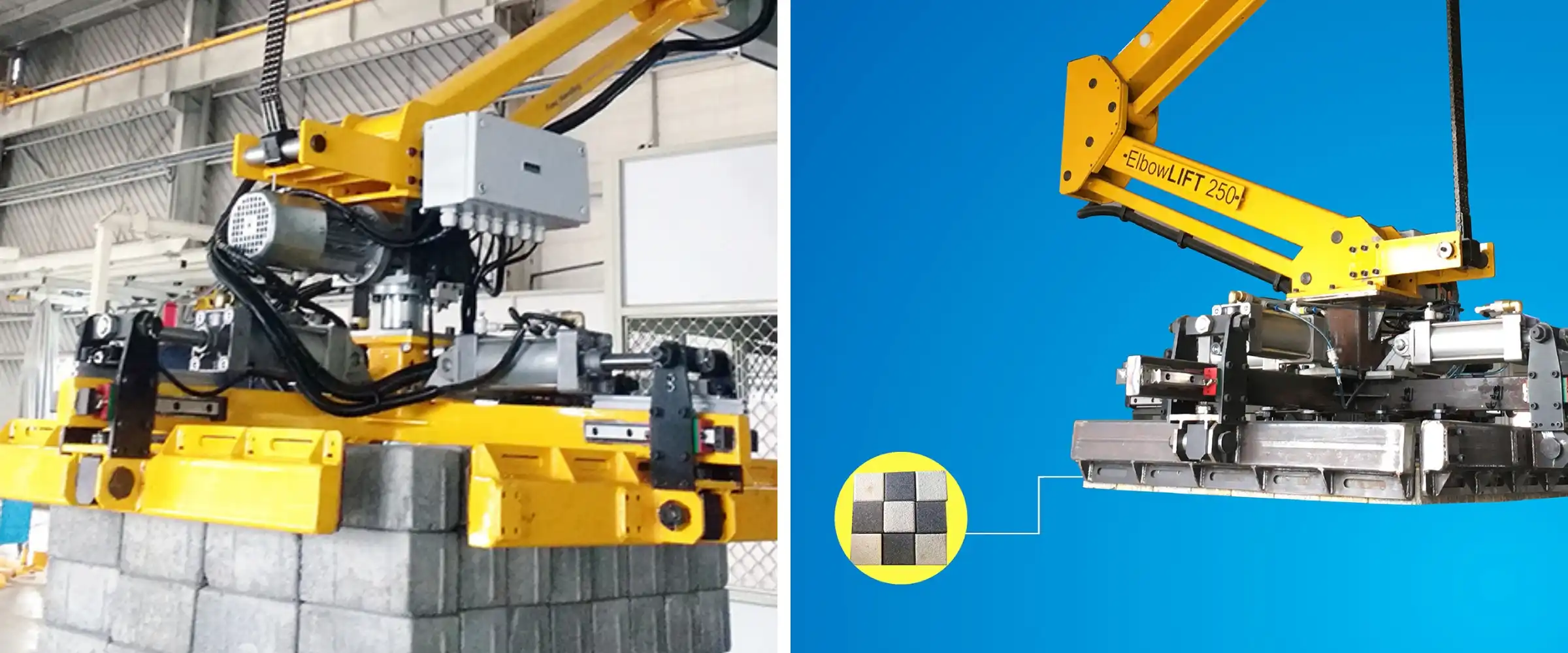

Gearboxes and Components Handling

Gearboxes and components handling in automotive manufacturing poses challenges related to weight, precise alignment, and operational efficiency. Fine Handling offers a variety of innovative material handling solutions in the manufacturing, assembly, testing and installation of gears, gearboxes and transmission components.

Improve ergonomics when lifting, carrying or manipulating Gearboxes and Components

Industrial manipulators reduce ergonomic strain by supporting the weight of gear boxes. Specialised grippers ensure precise alignment, minimizing assembly errors.

- Gearboxes are weighty, straining workers during manual handling.

- Accurate placement is crucial for gear meshing and assembly integrity.

- Swift handling is essential to meet production line cycle time targets.

Manipulators enable swift, accurate positioning, enhancing production line efficiency. Grippers with safety mechanisms prevent drops and accidents, enhancing worker safety. Grippers with safety mechanisms prevent drops and accidents, enhancing worker safety.

Industrial manipulators and customised grippers enable safe gearbox and component handling, elevating operational effectiveness, worker well-being, and overall manufacturing efficiency. These solutions play a pivotal role in enhancing safety, accuracy, and productivity within the automotive and gear manufacturing industry.