Forged and Cast Component Handling

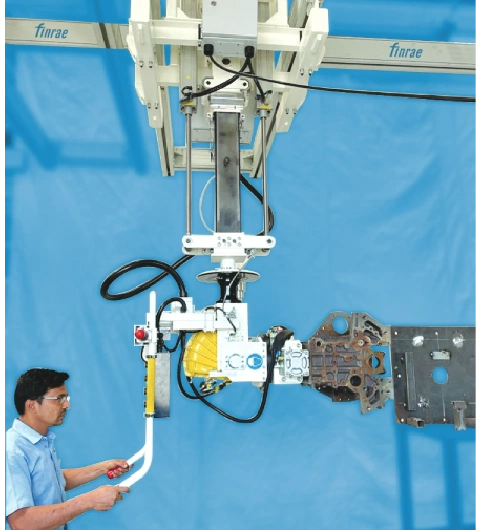

The vertical lifting and movement of heavy automotive chassis present several challenges due to the weight and size of the components involved. Fine Handling has developed and supplied innovative solution for vertical lifting and movement of chassis within the plant or across stations.

Improve ergonomics when lifting, carrying or manipulating Forged and Cast Components

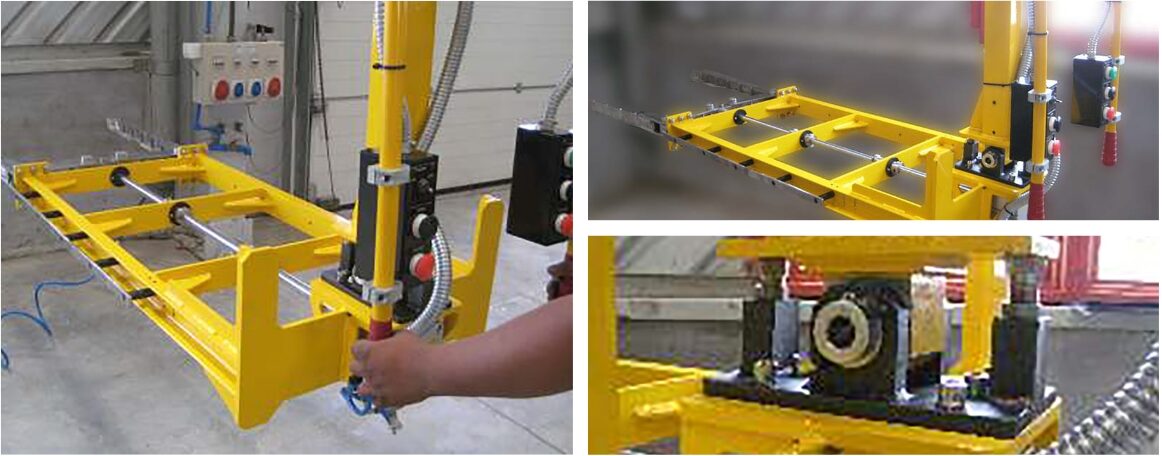

Special industrial manipulators with custom grippers quickly handle forged and cast parts, speeding up manufacturing. It helps accurately position and align parts during assembly. Grippers reduce manual lifting, lowering the risk of worker injuries.

- Forged and cast components can be exceptionally heavy, straining workers and posing safety risks.

- Components often have complex, irregular shapes, making them difficult to grasp securely with conventional tools.

- Traditional handling methods can be time-consuming, affecting production efficiency.

Grippers are made to ease and ergonomic handling, reducing worker fatigue and boosting productivity. They're adjustable for different parts, sizes, and materials, fitting various automotive needs. Grippers are designed to protect fragile surfaces on parts, minimizing the risk of harm.