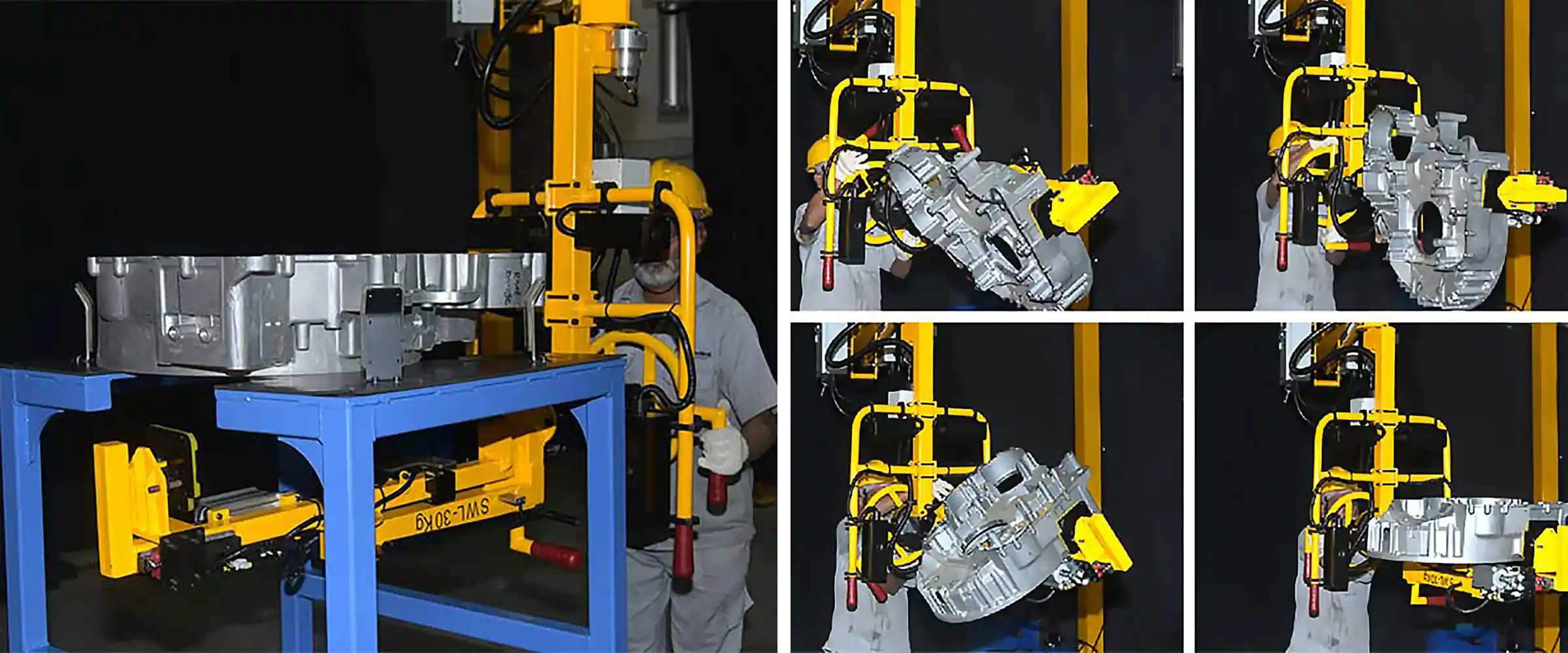

Easy placement of Flywheel housing

Easy placement of Flywheel housing

Requirement of a manipulator which would handle a flywheel housing across whole line from trolley to final packaging stage, during which multiple operations would be performed on the housing. A single gripper was required to carry the housing to all the tables and it also included rotation of housing in different directions.

Challenges

- Lifting and balancing weight of complete chassis approx. 250 kg

- Handling weight of complete chassis approx. 250 kg

- Precise placement with tolerance of 2 mm

- Prevent possibility of accidental touch between the cylinder and the Car body

Solution and Benefits

- Lift Specialised 4 clamp gripper was developed which could pick and balance the component.

- Transfer Rail mounted ElbowLIFT was developed which could travel in X-Y axis to achieve placement at any location. ElbowLIFT could place chassis at any height.

- Place Induction drive based automation Was provided to achieve precise placement with required tolerance.