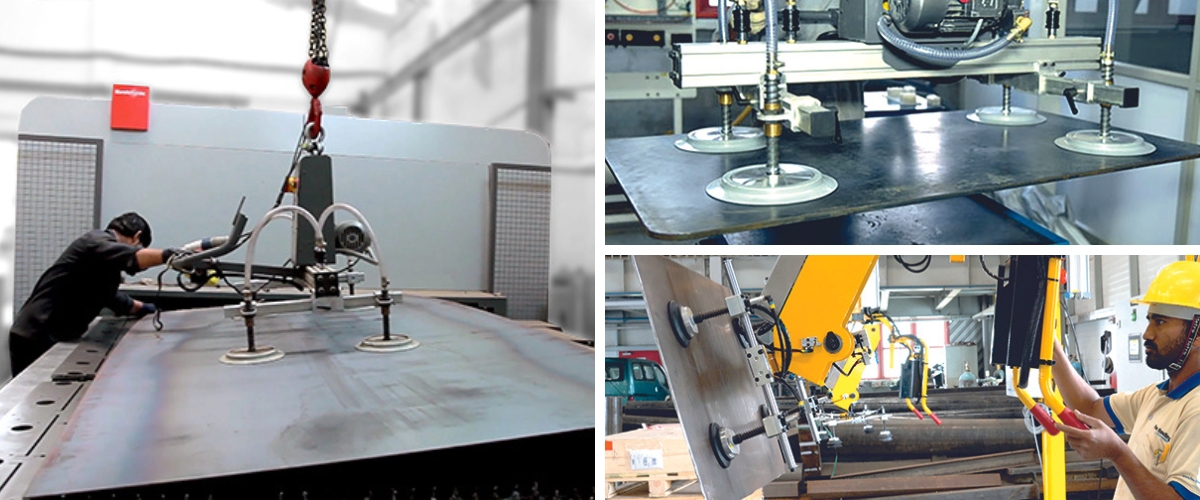

Precision Screw Compressor Handling

Accurate mounting of heavy engineering components, such as compressor screws or railway wheels, on sensitive testing machines presents several challenges due to the size, weight, and precision required for the process. Fine Handling has developed specialised handling solutions for such demanding applications.

Improve ergonomics when lifting, carrying or manipulating Precision Screw Compressor Handling

Industrial manipulators are made for handling large and heavy objects accurately. They give precise control over positioning and alignment of these components, improving safety by reducing the need for manual lifting. This cuts down on accidents and injuries.

- The sheer weight and size of components weighing more than 200 kg can make handling and mounting difficult.

- Achieving precise alignment is critical, especially when mounting components for testing.

- Handling heavy components poses significant safety risks to workers.

- The testing machines themselves need to be compatible with the size and weight of the components.

- Sensitive testing machines are susceptible to impact, vibrations, or slip-ups which can impact the accuracy of measurements.

Manipulators enable quicker handling of sheets, reducing production downtime of costly machines such as bending, cutting etc. Customized grippers allow for seamless integration into automated workflows, optimizing overall cycle times.