Efficient Battery Handling for Automotive and Forklift

Battery packs for large batteries often contain heavy components, such as battery cells, cooling systems, and structural elements. Manipulators equipped with lifting capabilities can handle these heavy components with precision, reducing the risk of injuries to human operators and ensuring safe and efficient assembly.

Material Handling Challenges for Batteries

- The weight and bulky nature of Batteries make them heavy and cumbersome to handle, leading to ergonomic strain during manual handling.

- Safety risks include mishandling of batteries which can result in drops, accidents, and potential injuries.

- Cycle time constraints require swift and precise battery placement to maintain continuous operation, demanding streamlined handling.

Industrial Manipulators and Grippers for Battery Handling

- Ergonomic Relief Industrial manipulators counterbalance weight, reducing physical strain on operators.

- Customised Grippers Specialised grippers provide a secure hold on batteries, minimizing the risk of drops.

- Safety Features Grippers incorporate safety mechanisms to prevent accidental releases and enhance worker safety.

- Speed and Precision Manipulators ensure quick, accurate battery placement, reducing downtime.

- Workflow Optimization Efficient handling of batteries contributes to seamless operations, enhancing overall productivity.

Manipulators offer flexibility in programming and tooling, allowing for easy adaptation to different battery pack configurations and designs. This flexibility is particularly valuable in the rapidly evolving field of electric vehicles, where battery pack designs may vary among different models.

Industrial manipulators and customized grippers make battery handling easy, enhancing worker well-being, safety, and operational efficiency in both automotive, EVs, and other equipment such as forklift, Earth Moving Equipment etc.. The innovative solutions from Fine Handling play a crucial role in overcoming challenges and streamlining critical processes.

Related Stories

We are in Birmingham, UK IMHX 2022, the logistics

When the product is world-class, it’s bound to generate

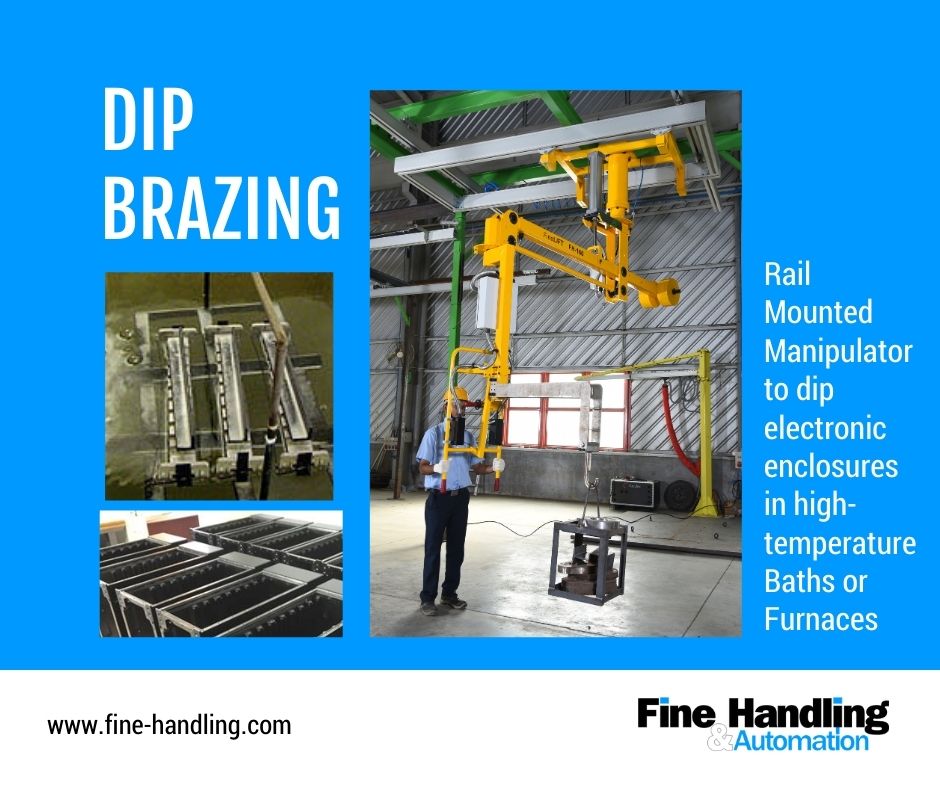

Solutions for Safe Handling of Components in High Temperature Furnace and Chemical Baths

Safe handling of components in high temperature furnaces or