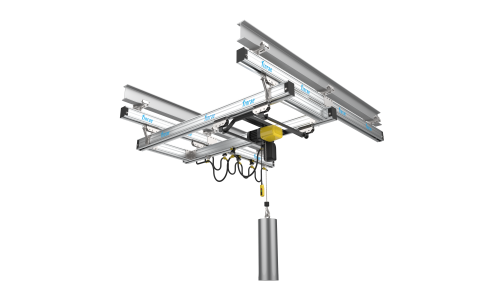

World-class Material Handling Solutions for Every Industry

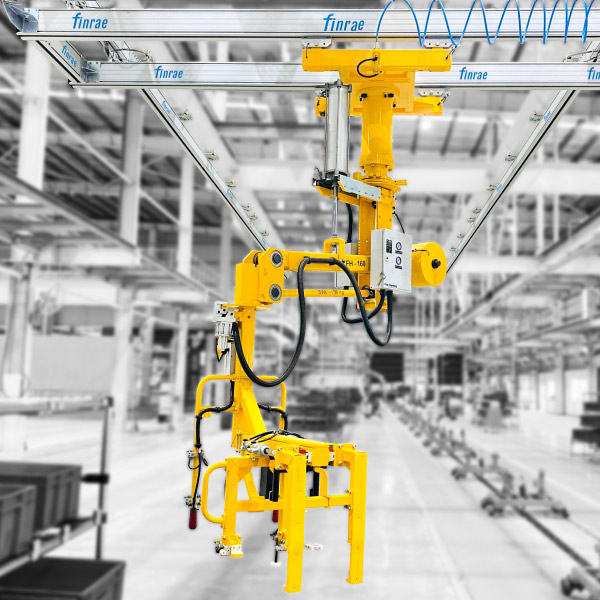

Fine Handling offers industrial manipulators, customised material handling solutions and automation for critical tasks. With over 20 years of recognition for innovations, expertise, and demonstrated success, Fine Handling has been a solution partner to all types of companies, starting from MSMEs to some of the world’s largest firms. Fine Handling’s material handling solutions are driving better productivity, safety and ergonomics in multiple industries and applications.

Industries we serve

2/3 Wheelers

Heavy Commercial Vehicls

Farm and Earth Moving

Locomotives

Logistics

Industrial Engineering

Diverse Industries

Lifting and Handling Solutions – Preferred Worldwide

Fine Handling has been pivotal in bringing world-class, innovative material handling solutions to diverse industries.

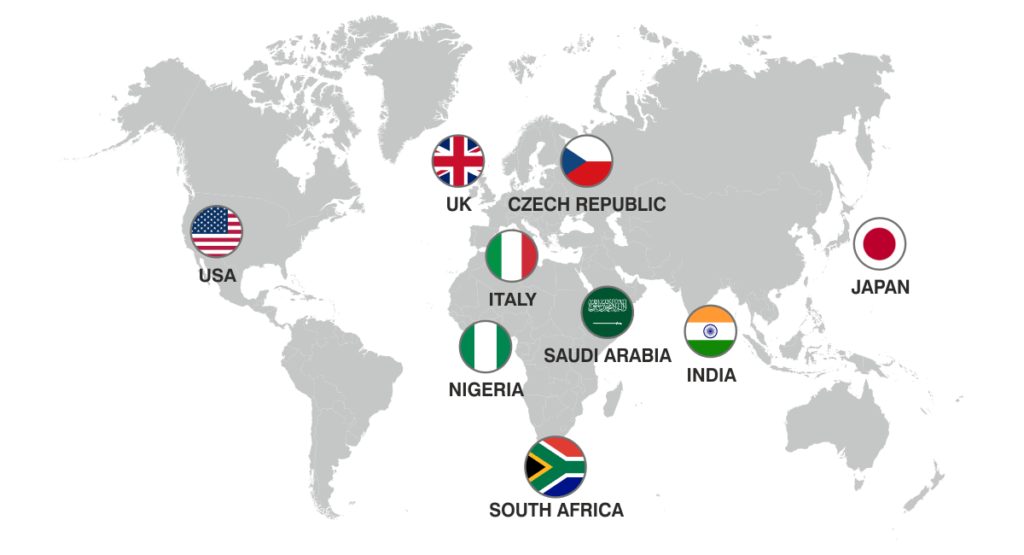

A winner of multiple awards for innovations, and successful exports to US, Europe, Africa, Middle East and Japanese markets, Fine Handling has evolved to be the preferred choice for total solution in and handling needs.

Installation worldwide

Years Of Expertise

Export Markets served

World Wide Exports

Key customers

Latest News

Industrial manipulators come

Industrial manipulators make